#Recycling / Circular Economy

Indorama Ventures expands deja(TM) portfolio to boost textile industry sustainability

Three key offerings add to the company’s deja portfolio, addressing customers’ main sustainability challenges:

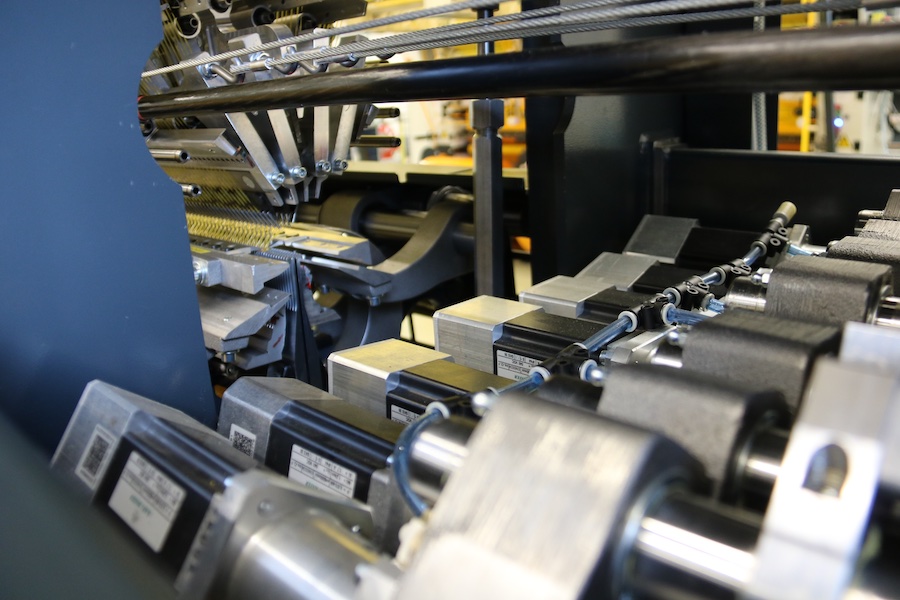

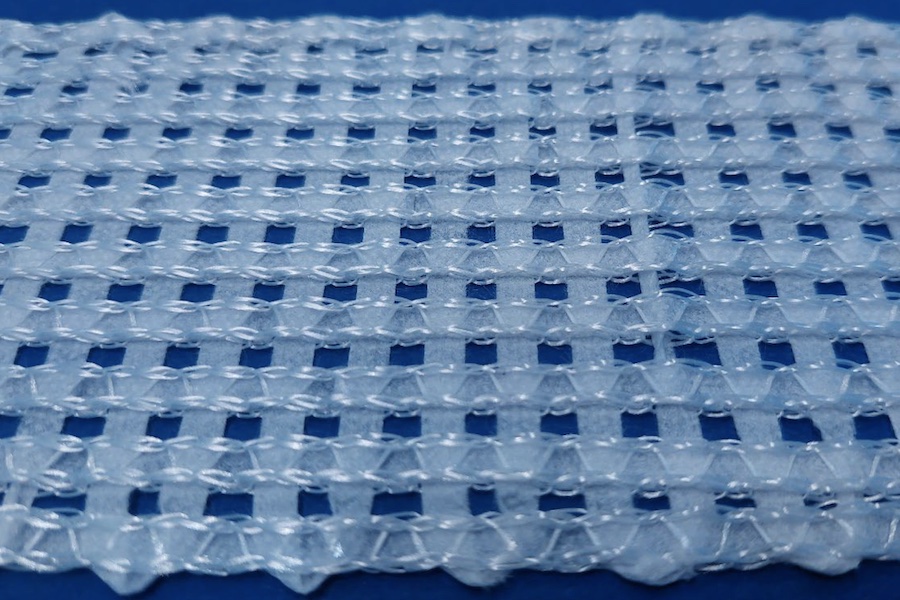

+ On-demand solutions for textile circularity, providing deja PET fibers and filament yarns made solely from enhanced recycled textile waste that was being discarded. Products available on customers’ request are high-tenacity yarns and cords for technical applications like airbags and seat belts, as well as fibers and filament yarns for lifestyle applications, such as apparel and home textiles. Customers interested to drive circularity and reduce greenhouse gas emissions, while keeping performance equal to standard solutions, are encouraged to request more information at enquiry.fibers@indorama.net.

+ deja Bio: Solutions to help customers reduce their carbon footprint. Thanks to its fully integrated, in-house PET supply chain, Indorama Ventures can deliver high-performing deja PET yarns out of Europe and Asia that have a substantially reduced carbon footprint. All of them comply with the accounting methodology of the ‘Together for Sustainability’ industry initiative.

+ Indorama Ventures takes a mass balance approach to increase the use of renewable sources, benefitting from eleven ISCC+ (International Sustainability and Carbon Certification) certified sites across its entire business, including PTA, PET chips, fibers, and technical fabrics. The mass balance approach is a chain-of-custody method that allows manufacturers to mix sustainable and conventional inputs like renewable and fossil-based materials in a shared production system, while still allocating the environmental benefits of the sustainable inputs to a portion of the output.

High-tenacity yarns and tire cord fabrics available in the bio-based deja portfolio allow for a progressive bio-content introduction into customers’ products. Customers can benefit from avoiding or simplifying qualification procedures and receive the same performance as from fossil solutions. Further, these products can be given new life through mechanical or enhanced recycling.

deja Enhanced: Products that give hard-to-recycle packaging and textile waste new life. In close collaboration with like-minded partners along the value chain, Indorama Ventures is also looking at ways to convert hard-to-recycle packaging into fibers and yarns through enhanced recycling. These solutions are readily available at similar level of performance as fossil solutions. In future, these products will also be supplied with flexible proportions of reprocessed textile feedstock to accommodate customers’ circular targets.

Customers and brand owners are invited to take a closer look at what the expanded deja™ fibers & yarns portfolio offers during Textiles Recycling Expo on June 4-5 in Brussels, booth no. 1825. As one of the leading events dedicated to textile recycling and circularity, this expo brings together industry leaders, innovators, and decision-makers to shape the future of sustainable textiles.

Claire Mattelet, Global Sustainability Program Head for Indorama Ventures’ Fibers Business, says: With the expanded deja portfolio, we are turning ambition into action – empowering our customers to meet their circularity and decarbonization goals through innovative, high-performance PET fibers and yarns made from textile waste, bio-based inputs, and hard-to-recycle materials. This is how we shape the future of sustainable textiles without compromising on quality or performance.”

With most of the textile waste globally being incinerated or landfilled, the global fashion industry accounts for an estimated 3 to 8 percent of total greenhouse gas (GHG) emissions. According to recent reports(1,2,) the industry’s emissions are expected to increase by about 30 percent by 2030 if no further action is taken(1). In response, Indorama Ventures has set a 2030 target of 40% of recycled and bio-based feedstock of its current commodity feedstock. Taking a leading role and collaborating along the entire value chain to drive sustainable practices in the man-made fibers industry is at the core of Indorama Ventures’ commitment to shaping the future of textiles.

(1) Global Fashion Agenda and McKinsey, 2020: Fashion on climate: How the fashion industry can urgently act to reduce its greenhouse gas emissions.

(2) The business of fashion and McKinsey, Nov 29 2023: The state of fashion 2024: Finding pockets of growth as uncertainties reigns