#Knitting & Hosiery

Producing the next generation of tricot fabrics – with ON drive

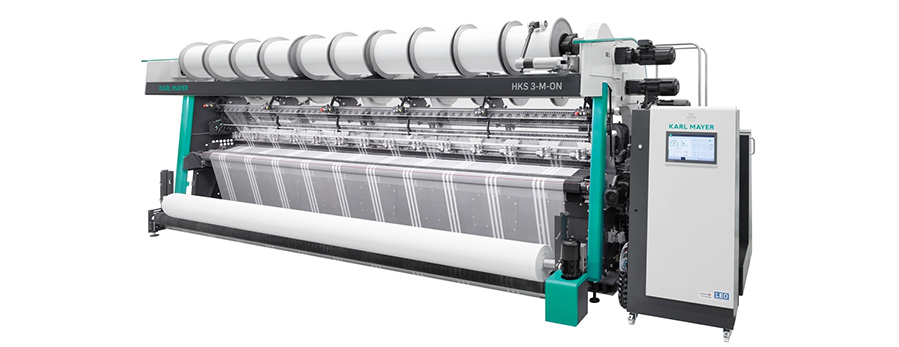

The HKS 3-M-ON, with electronic pattern drive and digital systems, was premiered at ITMA 2019

This new machine can reach a maximum speed of 2,900 min-1, depending on the working width. This makes it the fastest, high-speed tricot machine with electronic pattern drive that has ever been built. It is also just as fast as the current HKS 3-M model with N-drive, but it is also much more flexible.

Patterning at the highest level of flexibility

A wide range of patterns can be produced and changed quickly on the new HKS 3-M-ON. It is simply a question of ordering the required lapping from KARL MAYER’s WEBSHOP SPARE PARTS and loading the data to suit the guide bars from the company’s own cloud directly onto the machine – and work on the new article can be started immediately. Selected lappings from a pre-defined list are available to download free of charge when working one of the first patterns on a newly acquired machine. KM.ON’s industry computer, k.ey, is responsible for securely linking the HKS 3-M-ON machine to the KM.ON cloud, thus providing access to KARL MAYER’s digital world. Thanks to the electronic guide bar control facility, there is no need to make any mechanical modifications when changing the article, which used to be the case with the previous HKS 3-M version. This means that any repeat can be worked, without any tempi change. Kay Hilbert, the Head of Product Portfolio Management at KARL MAYER, says that the visitors were particularly impressed by this simple pattern change system, which does not require any mechanical intervention. “Many of our customers are faced with a change of generation amongst their staff.

Young people are computer-savvy, but people with specialist knowledge of the mechanical systems are hard to find.” Additionally, the ON drive eliminates the costs of buying, handling and storing pattern discs. With all the new possibilities offered by the HKS 3-M-ON, customers can reduce pattern-related stoppages considerably, increase productivity greatly, and react quickly to changing market demands. This innovative, high-speed tricot machine also delivers additional benefits, thanks to the new main drive system. The main shaft is now moved directly by the associated main motor. This system, together with the electronic guide bar drive, eliminates the need for wear-prone drive belts, and this has a positive effect on maintenance costs. Noise levels have also been reduced.

Sales launch in 2020

The new HKS 3-M-ON will be available in gauges E 28 and E 32 and in the working widths of 130", 180", 210", 238" and 280". Its wide range of features is opening up many possible end-uses for this three-bar HKS machine, which will be available as of 2020. The HKS 3-M-ON will go into production in the first quarter of next year.