#Industry 4.0 / Digitalization

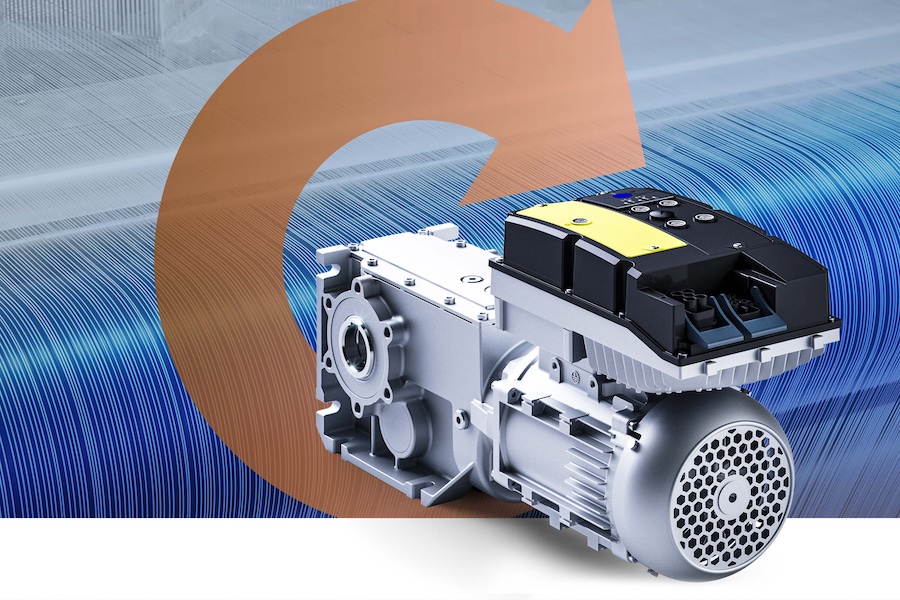

Lenze is taking drive performance to the next level with the i750 servo inverter

In the age of batch size 1 and ever-increasing competitive pressure in production, the bar for drive technology is higher than ever: Fast response times, absolute motion accuracy, intelligent algorithms and maximum productivity are considered basic requirements for competitive machine automation. Thanks to more than 75 years of experience in drive technology, Lenze knows these challenges inside out and now offers a powerful solution for motion control applications with its i750 cabinet multi-axis servo inverter. Björn Maltzahn, Motion Control Product Manager at Lenze, explains: "Our new servo inverter represents a consistent evolutionary development of our portfolio. The i750 masters complex applications and offers mechanical engineers new design scope for future-proof solutions."

Automation at the highest level

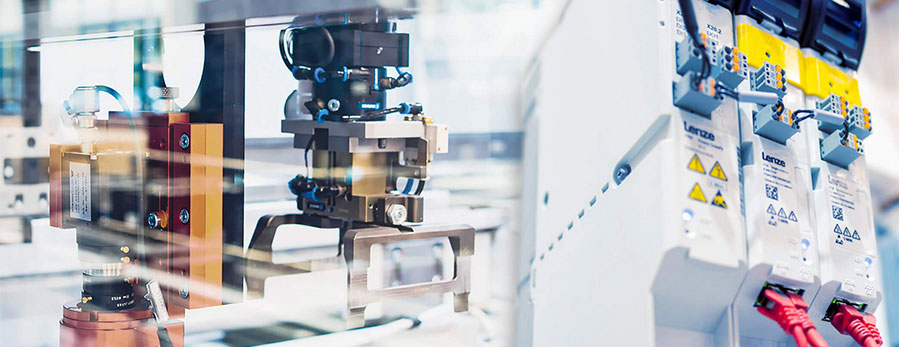

The servo inverter boasts outstanding precision and dynamics. Its outstanding control performance allows operators to increase the cycle rates of their machines by up to 20 percent. In combination with a Lenze controller, the auto-tuning function also makes commissioning much easier and improves machine efficiency. The i750 product range consists of power supply modules and single and double axes, which are operated in a DC network. Key features are a narrow width and extensive integrated safety technology. The units can be used universally in the power range from 1.1 to 15 kilowatts for single axes and from 1.1 to 7.5 kilowatts for double axes. Between 22 and 110 kilowatts, the i950 cabinet servo inverter acts as a power extension.

Unbeatable package

In addition to efficiency and precision, the new servo inverter stands out above all for its easy integration into the Lenze control systems, as Björn Maltzahn reports: "The i750 offers all the advantages of an open EtherCAT CiA402 interface and is used in centrally controlled system architectures. Its full potential becomes apparent in conjunction with the Lenze controls, making it an indispensable element in sophisticated automation systems. Users benefit from both maximum accuracy and higher throughput." Predefined and tested software modules in the Lenze FAST Application Software Toolbox significantly reduce development and commissioning times thanks to the product philosophy of "parameterizing instead of programming".

One-cable technology throughout

The i750 servo inverter series supports the operation of motors spanning the entire power range using one-cable technology (OCT). Björn Maltzahn considers this a crucial advantage: “One-cable technology saves users more than half the installation effort as well as valuable space in their control cabinets.” One-cable technology is possible thanks to the HIPERFACE DSL® open motor feedback protocol. Lenze motors and geared motors using one-cable technology include the MCS and m850 motor ranges, which are equipped with high resolution HIPERFACE DSL® encoders. The i750 servo inverter thus provides a complete drive system for highly dynamic applications.

Safe choice for the future

The development team also focused closely on the servo inverter’s new functional safety. Its integrated safety functions cover a broad range of safety-related machine applications. As a result, the device meets safety-related requirements up to safety integrity level 3 (SIL 3) and performance level e (PL e). Even more extensive options to safeguard machine functions are provided by extended safety functions such as safe-limited speed (SLS), safe direction (SDI), and safe-limited position (SLP). Björn Maltzahn summarizes the benefits: “Whether it is safety, precision, or performance, our new servo inverter and the corresponding product portfolio will give mechanical engineers and machine operators all the tools they need to meet any demands for drive technology.”