#Raw Materials

Global stocks projected to decrease 10% in 2018/19

Executive Summary

- Highlights from the September edition regarding the 2018/19 season:

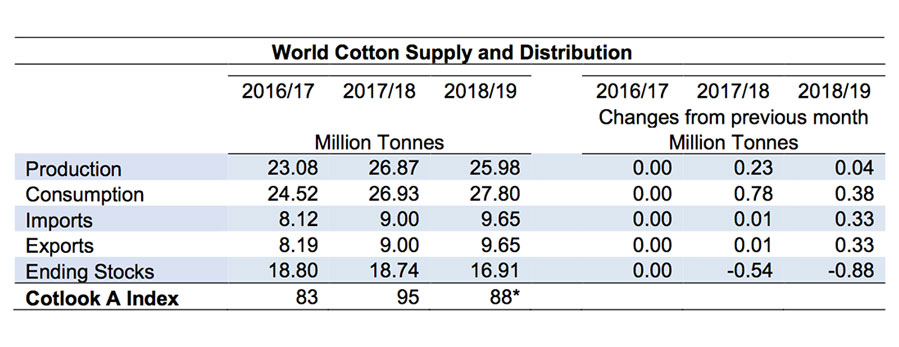

- Global production projected to decrease 3% to 26 million tonnes

- Consumption is projected to increase 3% to 27.8 million tonnes

- Global stocks are expected to decrease 10% to 16.9 million tonnes

- Stocks in China are poised for a 23% decline to 6.6 million tonnes

The decrease in global stocks will largely come from a drawdown in China’s warehouses. From March through August 2018, the Chinese State Reserve sold more than 2 million tonnes of fibre, reducing stocks to about 8.6 million tonnes.

If production and consumption remain at current projected levels, the 2018/19 season is expected to further reduce stocks in China to 6.6 million tonnes, reflecting a 23% decline.

Stocks outside of China are trending in the opposite direction, increasing 24% in 2017/18 to 10.1 million tonnes. The increase is expected to slow in 2018/19, ticking upward to 10.2 million tonnes. By the end of the coming season, warehouses outside of China are expected to house about 61% of the world’s global reserves.

Ending stocks in China reflect growing mill use in China and may signal the possibility of increased imports in 2018/19. Growing global demand in 2018/19, despite uncertainty about trade policies, may lead to price increases amidst a possible global production decrease.