#Industry 4.0 / Digitalization

From spinning to finishing - Lenze makes textile machines more efficient

"Digital solutions help our customers improve their total cost of ownership while implementing new business models. By combining operational technology (OT) and information technology (IT) and using the digital twin across the entire machine lifecycle, they become more efficient, save engineering time, reduce energy consumption and conserve resources," explains Falk Vespermann, Global Segment Manager Textile at Lenze.

Lenze sees itself as a partner to its customers and supports them in their digital transformation. The open automation platform Nupano is just one example of this: it forms the bridge between the IT and OT worlds and enables customers to bring applications (apps) into their machines, even without their own IT expertise, and thus differentiate themselves in the market. Vespermann adds, "Digitalization is having a huge impact on the world of machine builders in the textile industry. Nupano is a key technology for bringing innovation into the machine and leveraging the potential of digitalization at machine and plant level in a simple and value-adding way. Our customers can offer new digital products, increase the efficiency and sustainability of their textile machines and generate more recurring revenue with their customers." Interested parties can listen to Falk Vespermann's presentation at the InnovatorXchange in Hall 3 on Sunday, June 11, 2023 at 3:20 pm.

Competitive advantages through digital solutions ?In addition to Nupano, Lenze can come up with many other concrete digital offerings. In Hall 9, Stand A301, the automation specialist will be showing innovative solutions such as condition monitoring. No extra sensors are needed for this, because the data already comes from the drive. Lenze also uses AI for machine optimization and offers an Asset Performance Platform that creates transparency about the installed components and ensures improved machine availability. The portal is linked directly to the OEM's machines. If a fault occurs, the machine can automatically create a ticket so that service technicians are informed at an early stage. The ticket shows which component is affected, which model or variant is involved, what the serial number is, and how the component was installed in the machine's topology. Incorrect information due to outdated documentation is ruled out: The information comes directly from the PLC, which always reflects the consistent actual state. Since the platform is manufacturer-neutral and relies on open standards, not only Lenze products can be queried. "In this way, downtimes can be avoided, throughput times can be optimized, and the OEE (overall equipment efficiency) of the machines can be increased," says Vespermann, summing up the benefits.

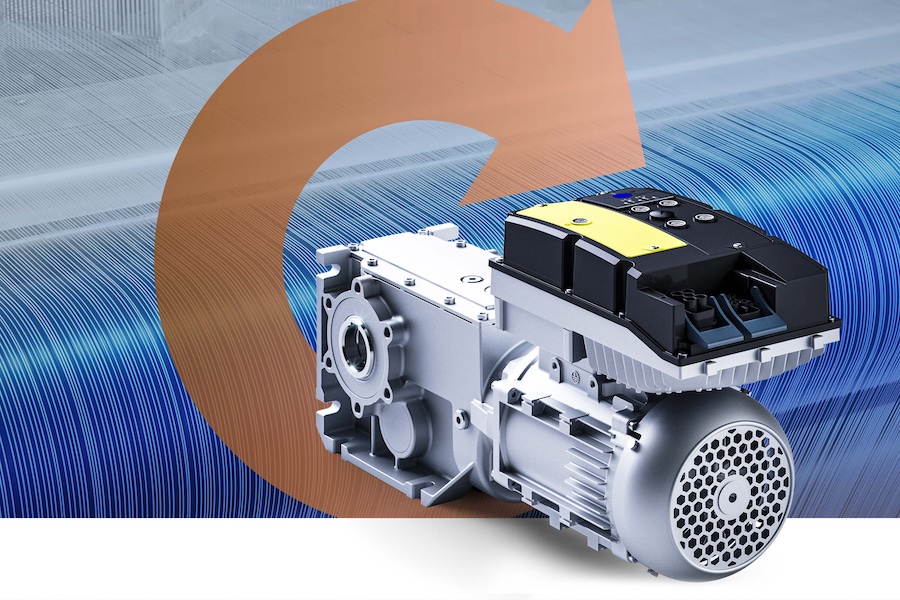

Seamless transparency for more sustainability?The planning of a machine is complex and decisive for the subsequent efficiency and sustainability in production. That is why Lenze offers the right tools for the hardware, but also for the software in the machine. They enable fast and optimal drive design with the right dimensioning and the lowest possible energy consumption.

Precise drive dimensioning, the use of high-efficiency products and regenerative energy form the basis for optimum energy efficiency and resource conservation. In addition, to meet increasing legal requirements, Lenze is already working on the digital product passport (:).

In the future, the : will transparently display all environmentally relevant data on the installed components or a machine, and will provide the basis for efficient recycling management. The basis is the digital twin, which can be created with Lenze's engineering tool, EASY System Designer, as early as the planning phase. It makes transparent what a machine is made of and how processed materials can be recycled in a targeted manner - an important step towards reducing the industry's ecological footprint.