#Industry 4.0 / Digitalization

Mechatronic Competence Campus (MCC) opens in Extertal

In the MCC, the automation specialist brings together the fields of electronics and electromechanics to accelerate processes from development to production. Employees are celebrating the company's 75th anniversary today at its headquarters in Groß Berkel and 13 locations worldwide.

Employees and their families celebrate 75 years of Lenze in Groß Berkel and worldwide

Planning started in 2016, the foundation stone was laid in 2018, and now the MCC has been opened to mark the company's anniversary. "Here at the MCC, we bring together what belongs together so that interdisciplinary teams can develop and produce sophisticated mechatronic systems even faster for our customers around the globe. And we are simultaneously optimizing our logistics with our automated high-bay warehouse," emphasized Lenze CEO Christian Wendler at the opening. "The MCC is a central component of our global growth strategy."

Babette Herbert, Lenze shareholder and granddaughter of the company founder Hans Lenze: "Extertal has always played a major role for us - after all, we are talking about one of the first Lenze production sites. Personally, I am very moved that we can help shape the future of Lenze right here and celebrate the opening of the MCC in the anniversary year."

The importance of the MCC for the economic region of East Westphalia-Lippe was emphasized by Dr. Axel Lehmann, District Administrator of the Lippe district. "Lenze's investment decision proves: Lippe is a strong region for strong companies - especially in industry. Thank you for this signal for the future and commitment to the location. And congratulations on the 75th anniversary."

Mayor Frank Meier also congratulated on the company's birthday and highlighted Lenze's long-standing commitment to Extertal. "Lenze and Bösingfeld - they have belonged together for decades. I am pleased that you, as one of the largest employers, are investing in the future of Extertal and setting an important entrepreneurial course here."

Worldwide festivities during the anniversary week

After customer and press events on Wednesday and Thursday, Lenze is celebrating its 75th anniversary this Saturday with family parties at 14 international locations, including 3,500 guests at its headquarters in Groß Berkel. Throughout the day, there will be live video broadcasts to the USA, China, Italy, and other countries to celebrate together virtually.

Lenze has chosen "The Courage of Change" as the motto for its anniversary year, addressing the courage to change that has characterized the company since its founding in 1947. This was also reflected in the sustainability campaign "#CourageforClimate", in which employees, their families, customers, partners, and other interested parties collected well over 75,000 kilometers for the climate between September 1 and October 15 - by running, swimming, biking, etc. In return, Lenze is supporting regional reforestation projects at various locations with a donation.

MCC at a glance: facts and figures

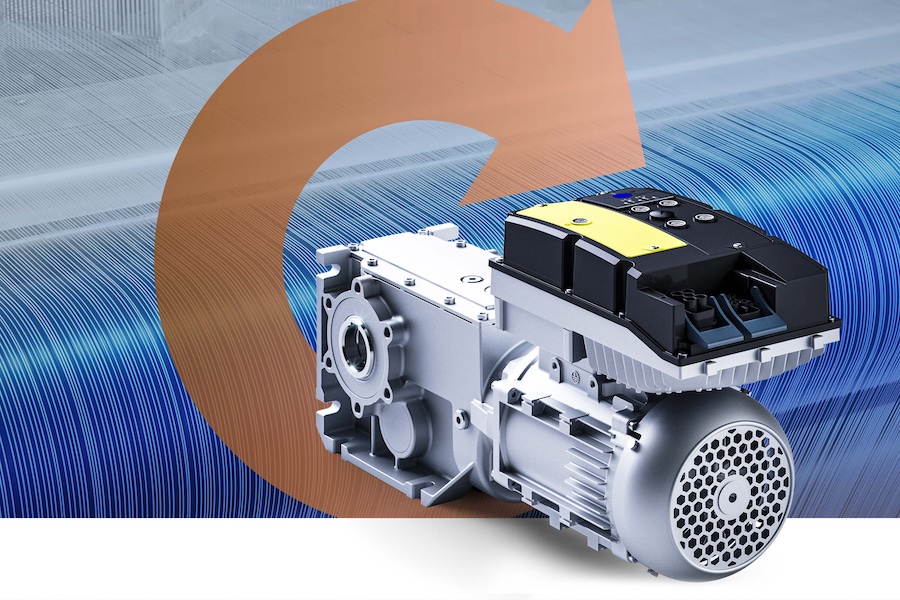

The MCC enables Lenze to increase its annual production capacity. In the future, around 150,000 geared motors, 200,000 servo motors, and, prospectively, 800,000 inverters will be manufactured in Extertal.

The consolidation of three locations dissolves departmental boundaries, promotes collaboration in agile, interdisciplinary teams, and shortens coordination paths - creating modern working environments in the spirit of Industry 4.0. The relocation of the electronics assembly from Aerzen-Groß Berkel to Extertal also creates growth space at the Groß Berkel headquarters.

The new logistics complex with the 24-meter-high high-bay warehouse comprises the areas of incoming goods, warehouse, production supply, and shipping. Trucks can be dispatched at nine gates.

The centerpiece is the ultra-modern high-bay warehouse. 300 Lenze motors are used in the drive technology. In total, there are 16,000 pallet spaces on 1,900 square meters and 15,000 containers on 400 square meters.

In the "supermarket" for assembly, ten employees ensure that the right goods are taken from 3,500 storage spaces and brought to production or shipping.

In the "Technikum," everything revolves around innovation. Around 100 employees will develop products for the factory of the future here - in close connection with the production.