#Industry 4.0 / Digitalization

36 talented young professionals begin their careers at Lenze in its anniversary year

Dr. Achim Degner, Chief Human Resources and Finance Officer at Lenze, welcomed the new colleagues on their first day and noted: "Lenze is celebrating its 75th anniversary this year under the motto 'The Courage of Change'. We have constantly evolved, moved forward courageously, and taken on new challenges. We are delighted that you are now also part of Team Lenze. Be just as courageous. Question the old, and be open to the new. Contribute your ideas and, with all your colleagues worldwide, shape the future of Lenze and thus also your own."

Thomas Czekanowski, Head of Education and Training at Lenze, added: "Automation is a business with a future and a very exciting career environment. We are happy to be able to teach you the necessary know-how and tools of the trade in your first years on the job. We are excited to see what career paths you will take and are always available to help and advise you."

After the welcome by the Executive Board, the training manager, and the responsible trainers, the first training sessions immediately followed. Since safety in the workplace is a top priority at Lenze, everyone was first given a pair of work safety shoes. Then Bernd Kirsch and Tim Fasse, trainers at Lenze, explained the most important rules for working safely. After a joint lunch, Christian Beyer, also a trainer at Lenze, took up the topic of IT security while accompanying the new colleagues during the first start of their new workstation computers. He paid particular attention to the ubiquitous topic of cyber security. The first day at Lenze ended with a company rally.

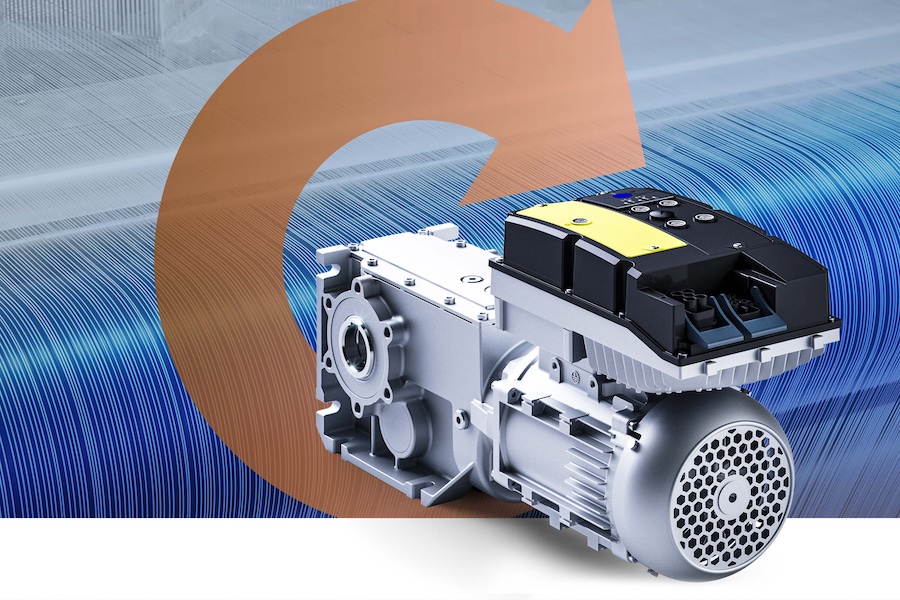

Lenze offers a wide range of degree programs and apprenticeships, for example digital logistics, industrial engineering and technical informatics, industrial clerk, electronics, and mechatronics technician. The training is a mixture of digital learning content and personal on-site support. Some courses are taught in the company's training workshop, while others are taught directly in the factory.

Depending on demand, training and study positions are advertised in the various professional fields. Internships are also possible. This way, students can try out the direction they want to take after school. For 2023, Lenze is still looking for young professionals who want to drive the transformation in automation forward in the long term. For more information, visit https://ausbildung.lenze.com.