India ITME 2012

Van de Wiele and Bonas at India ITME

The Velvet Tronic VTR is manufactured in a plain/dobby execution - VTR23 – and a Jacquard execution – VTR33 (Pic. 2). The applications of velvet are numerous: upholstery, automotive, bus and train, curtain, chiffon dress, artificial fur, etc. For the interior fabrics, there is a fashion towards the Italian Velvet with pile design combined with Jacquard ground effects. Van de Wiele is giving a new life to this Italian velvet by creating a new quality with 3 pile colours in center draw and 2x4 backing yarns per reed dent. The design possibilities become unlimited, especially when combined with a filling selector. The LJVi3 jacquard is equiped with 11520 solenoïds. The Velvet Tronic VTR42 is a special execution for technical fabrics such as distance fabrics and paintbrushes.

Pic 2: Velvet Tronic VTR33 for Italian Velvet equipped with a LJVi3 jacquard of 11520 solenoïds for 3 pile colours in center draw and 2x4 backing yarns per reed dent

Van de Wiele has succesfully introduced it’s new Innovator-range of carpet weaving machines on last ITMA. Now the range has been extended with the Handlook Carpet Innovator HCi X2, using 3 rapier technology, producing 50% more than double rapier machines, very nice carpets with a hand-knotted look backside. The maximum reed density has even been extended to 1000 d/m with 8 colour frames, being the most dense machine-made handlook carpets available on the market, with more than 2.000.000 points/m². Samples of this innovation are displayed at the Van de Wiele booth. The HCi X2 is the reference for handlook carpets in Iran, Turkey, Belgium, China, in reed densities from 240 up to 1000 d/m.

The Rug & Carpet Innovator range is now available in a 5 m weaving width execution, for optimized combinations of area rug dimensions. Studies have proven that the 5 m wide carpet weaving machine of the Innovator range compared to the traditional 4 m wide has a payback of less than 2,5 years. This is valid for traditional design carpets and modern rugs with loop and cut pile, up to 10 colours, sisal look carpets, outdoor carpets and shaggy carpets.

Super Shaggy long pile area rugs, up to 2 x 70 mm pile height, woven on the Shaggy Rug Innovator SRi02, are introduced to the carpet weavers.

Artificial grass, woven on SRi02 with patented weave structures in W, for good pile fixation without backsizing, is displayed.

The SRi02 is also built in 5m width to weave e.g. artificial grass in 15’ pile width.

Combining high cut pile and high loop pile, rugs with a rich texture woven on the Universal Shaggy-loop Innovator USi03, are on display.

Numerous samples displayed on the booth will demonstrate the advantages of the MAX91, both for contract wall-to-wall carpet as for area rugs.

The Master in Axminster MAX91 is designed to weave at high industrial speed of 160 rpm and up to 16 colour frames without incorporated pile.

Many Van de Wiele MAX91 Axminster carpet machines are already equipped with a Smart Creel, replacing the labour intensive and unflexible traditional bobbin creel. This robotized creel is now also available for the AWi01 wire weaving machine (Pic 1).

Bonas will present and demonstrate:

Low power consumption:

Bonas is going to satisfy all Jacquard weaving needs with only two models: ZJ and LJ. Both boast harmonic mechanism driving low friction selectors. Both benefit from low torque, low mass and low inertia. And both models, despite strength and agility, use only a minimum number of mechanical connections - one shaft connects both sides of lifting arms, but because of light torque, without excess torsion. With their LJ range, designed with bigger capacity hooks sizes in mind, they use dual cam box for concise shed control and dwell shed capabilities. The power consumption of the solenoids, always low compared to other weaving processes, has even been reduced massively over the past two generations of Bonas Jacquard machinery.

Both boast harmonic mechanism driving low friction selectors. Both benefit from low torque, low mass and low inertia. And both models, despite strength and agility, use only a minimum number of mechanical connections - one shaft connects both sides of lifting arms, but because of light torque, without excess torsion. With their LJ range, designed with bigger capacity hooks sizes in mind, they use dual cam box for concise shed control and dwell shed capabilities.

The power consumption of the solenoids, always low compared to other weaving processes, has even been reduced massively over the past two generations of Bonas Jacquard machinery.

Low maintenance:

With the accessible greasing points it is not necessary to remove machinery covers. Their patented solenoid – attracting hook- to latch selectors, with only one moving part is exempt of any maintenance or lubrication – a major advantage when accessible Jacquard sizes frequently within use are 6144 hooks or above.

100% Diagnostics:

Bonas stands for selector simplicity. Thier motto is “Relax safe in the knowledge of fault free fabric” and the company says that the Bonas selector, with its inherent 100% electronic principles, gives 100% diagnostic, fault control. Other important factors – temperature, air flow, design integrity and many others – are closely monitored, managed and cared for. The whole intelligent system is powered by current drive technology, delivering the correct amount of power, always, despite whatever inconsistencies the outside power supply may have.

Adjustable Split heck:

Bonas customers can free their yarns from the stresses of reed beat up. The adjustable split heck improves quality and efficiency.

Terry Warp Separator:

And Bonas customers can manage and control their pile yarns without additional processes or equipment. Because of the sound selector principals and the technical innovation towards weaving BONAS creates two separate sheds, within the geometry of the moving mechanism. They control one shed for the pile and the other for the ground. Adjustments are infinitesimal, thus allowing increased efficiency, increase in quality and a growing confidence for flamboyant designs!

Flat fabric Warp Separator:

Infinite warp separation eliminates yarn damage or shadow effects on finished woven fabric. Again, because of their sound selector principals and their technical innovation towards weaving they have created two separate sheds, but using odd and even rows to differentiate. Same efficiency improvements can be expected and, just as importantly, so can the easy adaption of more complex designs with varying ranges of yarn types, sizes and quality.

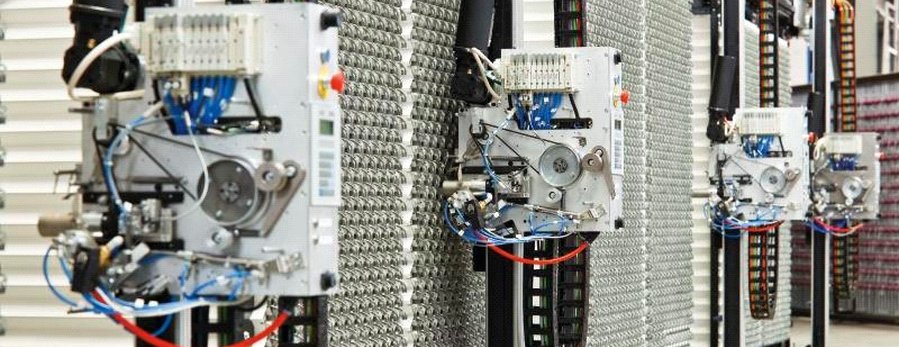

Pic 3: Bonas LJ range for all applications (presented model: LJ11-48)

Following Jacquards can be seen during the exhibition:

- 8200 hooks shedding system on Picanol Optimax-190, weaving High Fashion Apparel

- ZJ2-28-2484 on Itema Rapier, double width, weaving Furnishing Fabrics