#ITMA Asia + CITME 2018

Artificial Intelligence (AI) – Creating the digital yarn factory

Reliably and efficiently manufacturing superlative quality – that is the wish of every yarn, fiber and nonwovens manufacturer. However, optimally adjusting manufacturing with constantly-changing products is a huge challenge: because even small deviations can have a massive impact on the quality of the end product.

To better monitor and control production across all systems against this background, globally technologically-leading machine and systems constructor Oerlikon has expanded its Manmade Fibers segment portfolio to include new digital products and services. By integrating the know-how of the recently-acquired German industrial automation solutions specialist AC-Automation, Oerlikon now offers Industrie 4.0 systems solutions from a single source: the entire manmade fiber manufacturing plant is – step by step – being automated, digitalized and expanded to include new functions.

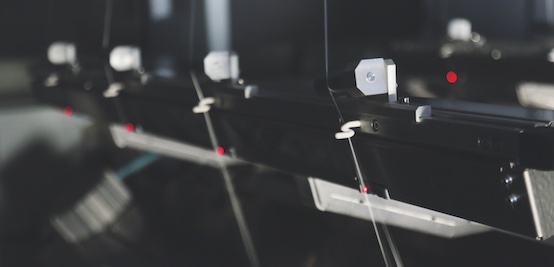

This starts with human machine interfaces (HMIs), which have enabled hugely interesting services – whether process monitoring via a service online app on smart phones and tablets or customer care and maintenance using the Microsoft HoloLens solution. The possibilities range from expanding the ‘From Melt to Yarn, Fibers and Nonwovens’ process chain to include upstream and downstream steps. Because it makes sense in the future to include those processes – such as automatic labeling or yarn package, fiber and nonwoven bale logistics – to date covered by means of third-party solutions.

Edge computing and cloud solutions

All these functions and services are – together with the Plant Operation Center (POC), which at Oerlikon assumes the function of a manufacturing execution system (MES), including the link to superordinate ERP systems – provided by the Oerlikon Digital Services platform. The machines, systems and third-party systems are networked and integrated by means of power edge computing and cloud solutions based on the OpenStack industry standard. This means that the data are utilized at the customer site as far as possible and only transferred to the central Oerlikon customer data center if required – and only following customer approval. Here, data security, data minimization and transparency are extremely important: “Needless to say, we process all data in accordance with the new European General Data Protection Regulation (GDPR), taking all further international data protection standards into account. Our customers always know which data we use and why”, explains Mario Arcidiacono, Business Intelligence & Data Warehouse specialist for the Oerlikon Manmade Fibers segment.

Scalable IT architecture

This IT architecture guarantees infrastructure management without operational downtimes – while the system and virus protection are always automatically updated. A further significant benefit is the scalability of the hardware and software, which can be adapted as needed in the event of changing requirements.

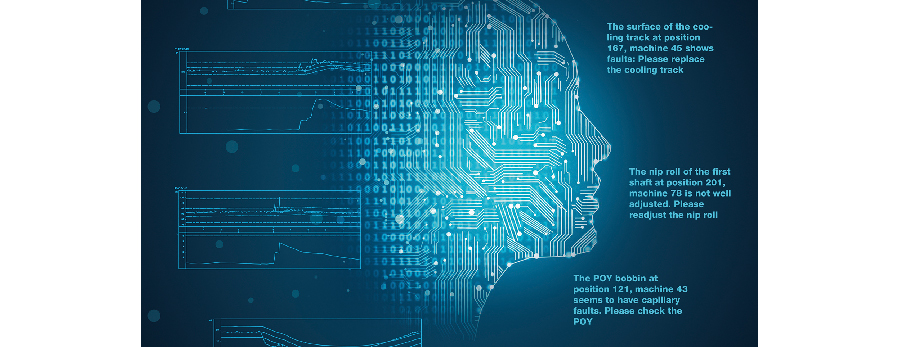

Sensors in the polycondensation system, the spinning plant and the texturing unit generate huge volumes of data, further increased by additional information such as drive data and target values, for instance. Collating such a mass of data however only makes sense if they are also automatically, swiftly, intelligently and reliably processed. An example: In the texturing machine, the Unitens® monitoring sensor continually measures the yarn tension at all positions. An error is generated if a measurement value does not lie within the prescribed tolerances – easily creating 125,000 graphs or more a day! In ever more cases, the form of the graphs can provide information on the error causes and ultimately provide targeted and efficient response to these. However: “Analyzing the graphs is currently carried out manually, which is very time-consuming. Hence, comprehensive data analysis and optimization of the production is in principle not possible using manual means”, states Jörg Huthmacher, Senior Manager Digital Transformation for the Oerlikon Manmade Fibers segment.

‘Our aim is your success’

How can these data now be sensibly processed? Here, new technologies such as machine learning reveal opportunities that have to date been locked. “In future, our latest digital solution – we are calling it ‘artificial intelligence manufacturing’, or ‘AIM4DTY’ for short – will provide help for texturing machine and systems solutions”, says Jörg Huthmacher. AIM4DTY is a digital system that is being ‘trained’ using trend charts and their respective errors. The result is a digital customer service that determines the probable causes of quality impairments. The information is instantly available to customers, therefore allowing them to immediately optimize the quality during running production. New information is acquired by linking the most diverse production data. This allows not only the continual optimization of the production process, it also ensures that predictive maintenance is now a reality – for superior yarn quality, greater process reliability and improved system efficiency.

Unitens® is a trademark of Saurer Fibrevision Ltd.