#ITMA 2023

Loepfe will present newly launched PRISMA Autoclearing functions at ITMA 2023

Textile Corner

Loepfe will demonstrate how its sensors keep yarn producers ahead of the competition by showcasing impressive achievements from Loepfe users in the Textile Corner.

Loepfe specialists will demonstrate how unique sensor technologies detect the smallest deviation in yarns, while clever software evaluates the signals to maximize quality and machine efficiency. Field study results, fabric examples and much more will be available for visitors to kick off exciting discussions.

Loepfe provides solutions for producers that need quality yarns at maximum machine efficiency. With the market's most advanced yarn monitoring systems, producers can reduce costs and waste, increase efficiency, and enjoy ease of use.

Clever yarn clearing

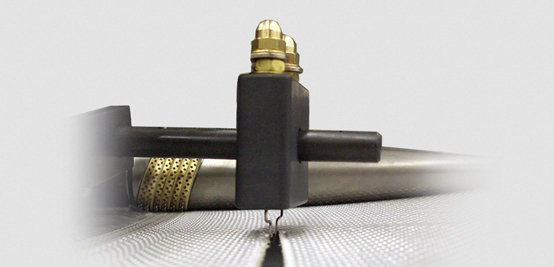

Loepfe focuses on the needs of producers and turns quality control into profitability through groundbreaking technology and clever software. Loepfe will showcase its market leading YarnMaster® PRISMA and YarnMaster® ZENIT+ technologies, both of which lead in technology, performance, and proven reliability for all applications in winding.

A special highlight at ITMA will be the newly launched PRISMA Autoclearing functions, which provide the perfect solution for ease of use in yarn clearing. PRISMA Autoclearing offers the most effortless yarn clearing experience on the market. Visitors can also test the full range of functions of the associated MillMaster® TOP data system, including trend analysis, planning boards for winding machine scheduling, clearer-assistant for cut forecasts, and more.

In the open-end sector, Loepfe will present our world renowned and well proven YarnMaster® EOS. This rotor yarn clearer is known for meeting the spinner’s requirement for consistent yarn quality and maximum machine efficiency.

Loepfe's offerings extend beyond the spinning sector, including the WeftMaster® CUT-iT for thermal fabric cutting and the all-rounder sensor WeftMaster® FALCON-i. The FALCON-i is known for zero-defect manufacturing, regardless of color, conductive materials, monofilament, or multifilament yarns.

Meet the team

Finally, visitors are invited to meet the Loepfe team, which has recently expanded with independent local business units in Turkey, India and China within the Vandewiele Group structure. Sales agents and service partners are now officially Loepfe colleagues, and they will be available at the Loepfe booth B205d in Hall 3 for interesting exchanges.