#ITMA 2019

Mayer & Cie. to exhibit fighting-fit quintet of machines at ITMA

Focus on sports - and athleisure wear

The MJ 3.2 E, a Single Jersey machine for body mapping; the OVJA 1.1 EETT, the specialist in knitted sports and leisure footwear; and the Spinit 3.0 E, which comes with new functions and can now process polyester. The new OVJA 2.4 EM mattress machine consistently fits into this environment in that peak physical performance demonstrably requires optimal regeneration.

ITMA machine No. 5 is the only one with no special sports connection but it is very much in line with the company’s innovative tradition. The prototype on show puts a tried and trusted process to a very modern use – with attractive benefits for customers.

“We see a great deal of potential in sports- and leisurewear, so the newly developed machines we are presenting at the ITMA are mainly in that area,” says Mayer & Cie. CEO Marcus Mayer, outlining his company’s ITMA focus. Current market studies underscore this view. According to Morgan Stanley, an annual average growth of seven per cent is to be expected till 2021 in this segment.

Made to map your body: the MJ 3.2 E

“Body mapping is one of the biggest trends in sportswear,” Marcus Mayer explains. “During sporting activity perspiration is greater in certain parts of the body than in others. Body mapping takes this factor into account by means of light and moisture-repellent areas.”

From the textile perspective, body mapping is a kind of mesh fabric with a central characteristic: the ground thread is usually thinner than the plating thread, but also can be used up to the same thickness. Supplying an elastomeric yarn at the ground or the plating thread provides for the required elasticity. In body mapping, the plating thread in combination with the ground thread of a different colour is responsible for the characteristic colouring.

The new MJ 3.2 E is Mayer & Cie.’s high-quality option for body-mapped fabrics. Unlike the Relanit 1.6 E, the previous option for body mapping, the MJ 3.2 E can process elastomeric yarns. Customers can expect an extraordinarily high level of secure plating due to less yarn fluctuation during the stitch formation process. The MJ 3.2 E also sets standards for productivity with a speed factor of 850 at 30 inches and an E 28 gauge.

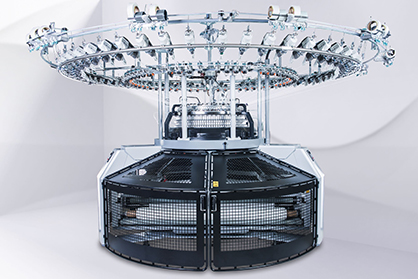

Pattern variety combined with productivity: the shoe specialist OVJA 1.1 EETT

Since the 2012 Olympics, sports shoes have been known to be available with knitted fabric uppers. All electronic Jacquard machines in the Mayer & Cie. OVJA range score points for productivity and short set-up times for shoe uppers. The main trend is toward multi-colour spacer fabrics with 3D effects, realised by lay-in yarns. And that is exactly what the new Mayer & Cie. OVJA 1.1 EETT can deliver. A multi-colour Jacquard machine with double electronics, it produces a wide range of patterns. This includes a variety of hole structures with bigger and smaller holes, thanks to double transfer. Thereby, the latest OVJA model combines top flexibility and high productivity. This combination takes the OVJA 1.1 EETT to the top rank of shoe machines.

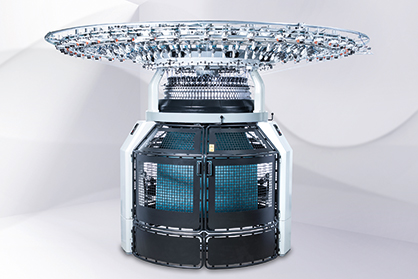

Most productive mattress machine in the market: the OVJA 2.4 EM

Regeneration and peak sporting performance are known to be closely associated. That is why, for Mayer & Cie., the OVJA 2.4 EM, its new mattress cover machine, fits neatly into the ITMA concept. “With this machine we offer our customers outstanding productivity along with variety of patterns and ease of use,” says Marcus Mayer, pinpointing the benefits of the OVJA 2.4 EM. It is the youngest member of the family of fully electronic OVJA machines and the premium machine star, producing up to 30 kg of fabric per hour, making it the most productive machine of its kind in the world, as demonstrated by a speed factor of 950.

In general it produces fabric weights of between 200 and 300 grams per square metre, but can also reach more than 500 grams per square metre. Thanks to an improved thread guide and its thread fluctuation control system the OVJA 2.4 EM is also extremely reliable. The horizontal weft thread guide on each cylinder segment ensures that customers can also look forward to improved user friendliness and a wide range of patterns.

Enhanced performance: the Spinit 3.0 E

The Spinit 3.0 E, in series production since the end of 2018, is part of Mayer & Cie.’s focus on sport at the trade fair. With “Enhanced Performance,” the circular knitting machine manufacturer has further developed its multiple award winning machine so that the spinning and knitting machine can now process polyester and athleisure and sportswear can also be produced on the Spinit 3.0 E. Speed is a further improvement; the latest model is, depending on the knitted structure, up to 20 per cent faster, in processing cotton as well as polyester.

“Digitization, which we are taking forward throughout the company, also improves machine performance,” says Mayer & Cie.’s managing director Marcus Mayer. “With ‚Digital Spinit, we are presenting attractive innovations for all three central aspects of any machine – Create, Operate and Control.”

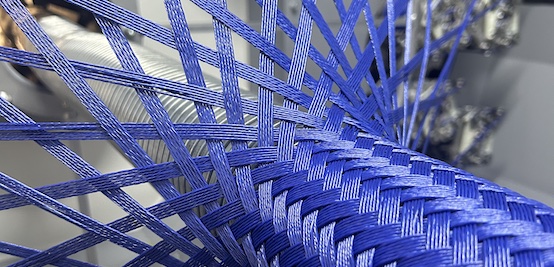

Taking innovation forward: Modern machine study of tried and trusted technology

“Along with the answers that we can provide to current requirements with the MJ 3.2 E, the two OVJA models and the Spinit 3.0 E,” Marcus Mayer says, “our philosophy includes regularly developing entirely new processes – such as spinitsystems for example.”

This year, Mayer & Cie. is doing justice to this aspiration by going back to a well-known process for the manufacture of textile surfaces. It offers the customer attractive advantages. For one, the material used is less expensive and the needle service life is longer than those of conventional knitting processes. For another, the fabric quality differs from that of conventional circular knitted fabrics. At ITMA, Mayer & Cie. wants to discuss future applications fields with their customers.