#ITMA 2015

Xetma Vollenweider presents its new innovations at ITMA 2015

The innovative technology portfolio of Xetma Vollenweider includes the product lines Soft Touch (emerizing & brushing), Plush Touch (raising), Even Touch (shearing), Level Touch (carpet shearing and finishing) and Clean Touch (fabric cleaning). With a wide range of applications in textile finishing for the apparel, home and technical textile industries, Xetma Vollenweider has concentrated on achieving unique surface effects.

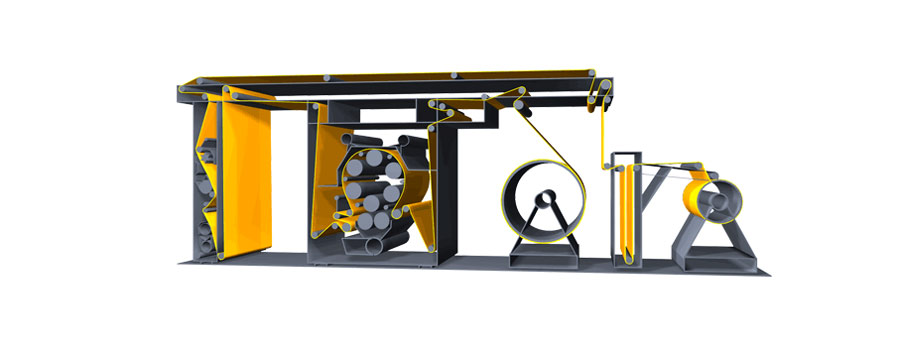

Here the combined brushing and emerizing system X-TREME XEB sets pioneering standards in the field of Soft Touch finishing of textile web. By combining the different technologies in just one operation, a more efficient production process can be achieved, thus allowing considerably higher fabric speeds and savings of processing passages. The latest model of X-TREME XEB will be shown at ITMA 2015.

As one of the most established manufacturer of shearing machines worldwide, Xetma Vollenweider can look back on more than 130 years of experience in this field. The shearing systems of Xetma Vollenweider guarantee, alongside high production speeds, a maximum cutting precision as well as the longest serviceable life of shearing units available. Xetma Vollenweider will exhibit its latest model of Optima XS1 shearing machine at ITMA 2015. Based on the long-term experience in carpet finishing, Xetma Vollenweider offers customized solutions for the mechanical surface finishing of textile webs in widths up to 6.0 meters. Besides its shearing systems Xetma Vollenweider will present unique finishing systems for pile cleaning and polishing of woven carpets and textile floor coverings.

With the acquisition of Haemmerle’s product line, Xetma Vollenweider extends its product diversity by the entire range of cutting systems for floating warp and weft threads and embroidery pattern separating threads. In combination with the high performance shearing systems of the Optima series, Xetma Vollenweider delivers complete finishing lines for embroidery articles and jacquard fabrics. The presentation of the new warp thread cutting machine X-CITE XF is only one highlight not to be missed at ITMA 2015.

Get yourself inspired by the new innovations of Xetma Vollenweider and discover its established product program in Milano in Hall 10, Stand F106.