#ITM 2022

ITM exhibitions addresses to a textile geography with a capacity of 60 million spindle shipments

The geography for textile manufacturing has changed location because of the fact that the developed countries operating in the ready-to-wear sector started to search for cheap resources in production. In the recent years, Asian countries, which hold the advantage of inexpensive manpower, have started to strengthen in the textile industry as the quotas in global exports have been revoked.

Considering the number of textile machines imported by North Africa, the Turkic Republic, the Middle Eastern, and some Asian countries until 2017 and through the spindle capacity they have, we observe that they have a share of 25% to 50% from the total market size (according to the machine type).

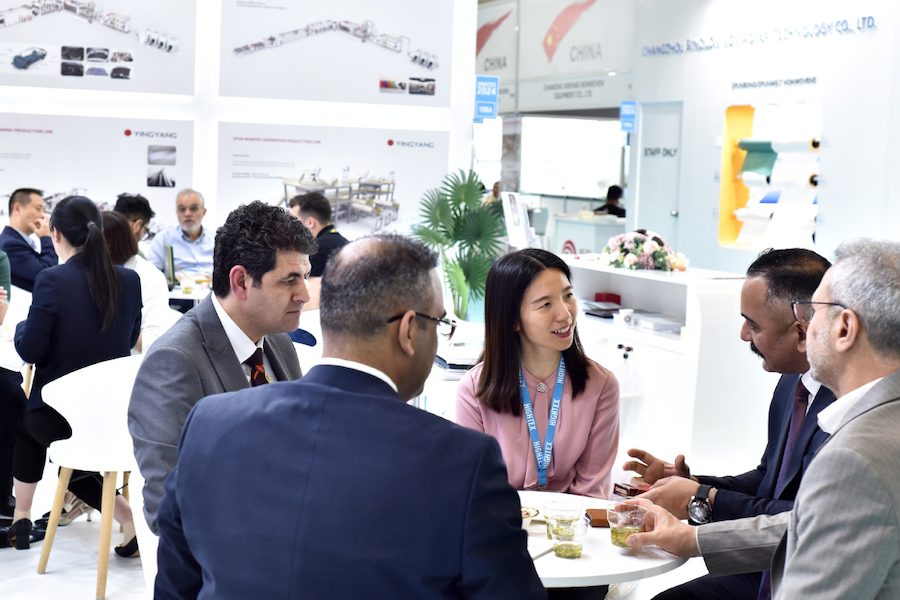

Organizing the ITM Exhibitions in Istanbul, where happens to be one of the most convenient geographical locations for the countries in these regions, in addition to ease of transportation and visa liberalization; transforms the ITM Exhibitions into a center of attraction for both exhibitors and visitors.

It is essential to take a look at the 'International Textile Machinery Shipment Statistics' report of 2018 published by The International Textile Manufacturers Federation (ITMF) in order to explain the significance of ITM Exhibitions in terms of the geographical location in which they are held.

Spindle, weaving, and knitting machine shipments carried out until 2017 together with the delivery rates achieved belonging to these machines between 2009 and 2018 to countries particularly Bangladesh, Indonesia, Pakistan,

Malaysia, and Egypt; additionally including Syria, Iraq, Iran, Algeria, Morocco, Tunisia, Turkey, Kyrgyzstan, Kazakhstan, Turkmenistan, and Uzbekistan are as follows:

YARN MACHINES

The spindle shipments (including short-staple spindles long- staple spindles, and rotors) made by the countries mentioned above until 2017 are 60 million pieces in total.

Short - Staple Spindles: Worldwide share among the total shipment is %24.

Long - Staple Spindles: Worldwide share among the total shipment is %9.

Rotors: Worldwide share among the total shipment is %25.

The total spindle shipments carried out the same aforementioned countries between 2009 and 2018 are approximately amount to 24 million pieces.

Short - Staple Spindles: Worldwide share among the total shipment is %18.

Long - Staple Spindles: Worldwide share among the total shipment is %45.

Rotors: Worldwide share among the total shipment is %14.

Observing these figures, one can easily comprehend the importance and significance of the geography that the ITM Exhibitions address which are organized in Istanbul.

TURKEY; THE SECOND HIGHEST GROWTH IN SHORT- STAPLE SPINDLE DELIVERY MARKET IN 2018

Turkey, being a textile country, is one of the world's leading textile machinery purchasing countries. The country invests large quantities of machinery in this subject both from the Western and the Asian and Far Eastern countries. The total purchases made by Turkey in 2017 amount to 1 billion 448 million dollars, while, in 2018, 1 billion 905 million dollars of purchases have occurred.

According to the records of the TSI (Turkey Statistical Institute); the total value of the imported textile machinery in 2018 amounts to 1.9 billion dollars where

523.2 million dollars of it is accounted for the machinery used in the preparation of yarns and fibers. The second place is taken by the weaving machines with $ 316.9 million dollars of imports and knitting and knitwear machines are in third place with 316.1 million dollars worth of import. The fourth most imported machine group was the machines used in textile finishing. 2018 imports of the machines in this group amount to 273.6 million dollars.

The report of Turkey in weaving and knitting machine shipments, and its spindle manufacturing capacity are considerably good. According to the ITMF report of 2018, the total number of spindles shipped in the yarn machinery division increased by approximately 126,000 pieces, to 8.66 million units compared to the previous years' deliveries. The markets showing the most growth in the short- staple spindle machinery shipments considering the global worldwide figures in 2018 compared to the previous year are South Korea with 834%, Turkey with 306%, Vietnam with 290%, and Egypt with 285%. The six biggest investors in the short-staple spindle machinery segment in 2018 are China, India, Uzbekistan, Vietnam, Bangladesh, and Indonesia.

TURKEY IS ONE OF THE WORLD'S BEST INVESTORS IN LONG-STAPLE SPINDLE SHIPMENTS

In 2018, long-staple (wool) spindle shipments in the world fell from 165,000 units to approximately 120,000 pieces. This outcome was mainly because of the decline in shipments to Asia and Oceania. Nevertheless, these regions remained their features as the strongest markets in long-staple spindle shipments. However, shipments to China and Iran also fell by 60%. The biggest investors in this section were Turkey, Iran, China, Italy, and Vietnam.

91% OF TOTAL GLOBAL ROTOR MACHINES SHIPMENT IN 2018 HAVE BEEN MADE TO ASIA AND OCEANIA

721.000 units of open-end rotor machines were shipped worldwide in 2018. Comparing to 2017 delivery numbers; this means an increase of 83.000 units. 91% of total global rotor machines shipments were made to Asia and Oceania,

and the total delivery has increased by 20% to 658.000 rotors. At the same time, China, which supplies the world's largest open-end rotor investments, increased its investments by 7% in 2018, while deliveries to Thailand, Malaysia, and Egypt are increased more than 3 times.

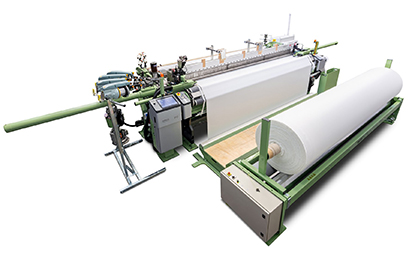

Weaving Machinery

Until 2017, the total number of weaving machines (Shuttle looms and shuttle-less looms) installed in North Africa, Turkic Republics, the Middle Eastern, and some Asian countries is approximately 900.000 pieces.

Shuttle Looms: : Worldwide share among the total shipment is %51.

Shuttle-less Looms: Worldwide share among the total shipment is %14.

The number of air-jet, water-jet and rapier/projectile weaving machines delivered to these regions between 2009 and 2018 is approximately 132.000 units.

Air-Jet: Worldwide share among the total shipment is %13.

Water-Jet: Worldwide share among the total shipment is %2.

Rapier/ Projectile: Worldwide share among the total shipment is %33.

TURKEY UNDERTAKES AN IMPORTANT ROLE IN RAPIER AND PROJECTILE WEAVING MACHINES SEGMENTS

Shuttle-less looms shipments in 2018 within the weaving machinery segment have increased by 39% worldwide, thus, reaching to 133,500 units of looms. Air-jet and water-jet looms deliveries have increased by 21% to 32,750 pieces and by 91% to 69,240 pieces, respectively. Rapier/projectile loom shipments encountered a decline by 5% to 31,560 units. In 2018, the most orders for shuttle-less looms globally came from the Asian and Oceanian continents, which made 93% of all orders. Similarly, 92% of all water-jet looms, 83% of all

rapier/projectile looms and 99% of all air-jet looms were also delivered to these areas. China and India were the biggest investors in all three categories. Weaving machine deliveries to these two countries accounted for 81% of the total global shipments. Turkey and Bangladesh, requesting a total of 18% of orders worldwide, have an important place in the rapier/projectile weaving machines segment.

Knitting Machinery

Large circular knitting machine shipments carried out between 2009 and 2018 to countries particularly Bangladesh, Indonesia, Pakistan, Malaysia, and Egypt; additionally, including Syria, Iraq, Iran, Algeria, Morocco, Tunisia, Turkey, Kyrgyzstan, Kazakhstan, Turkmenistan, and Uzbekistan account to a total of 45.000 units. Again, a total of 125.000 pieces of flat knitting machines were shipped to the aforementioned countries in the same time period.

Circular Knitting Machines: Worldwide share among the total shipment is %14.

Flat Knitting Machines: Worldwide share among the total shipment is %14.

ASIA AND OCEANIA COUNTRIES ARE THE WORLD'S LEADING INVESTORS IN CIRCULAR KNITTING MACHINES

The worldwide deliveries of large circular knitting machines decreased by 4% in 2018 to 26,300 units in total. In addition, Asian and Oceania countries became the world's leading investors, receiving 85% of all new circular knitting machines in this category. The largest investor was China with 48% of total shipments worldwide. India and Vietnam ranked second and third, with 2,806 and 1,406 units, respectively.

The electronic flat knitting machines segment decreased by 20% in 2018, to about 160.000 pieces. Asia and Oceania countries were the main markets with a 95% share in total global world shipments. China held its position as the world's largest investor in this category. This country, although its order of 154,850 units from the previous year fell to 122,500 units, retained 86% of worldwide shipments.