#Cinte Techtextil China 2018

ANDRITZ highlights its state-of-the-art technologies at CINTE 2018

As one of the global market leaders in advanced technologies for drylaid, spunjet, thermobonding, wetlaid, and converting processes for absorbent hygiene products, ANDRITZ offers reliable and unique solutions tailored to each customer’s individual needs.

ANDRITZ (CHINA) LTD. WUXI BRANCH – THE RIGHT PARTNER FOR THE ASIAN NONWOVENS INDUSTRY

The Chinese nonwoven market is on the rise in terms of capacity and excellent roll good quality, serving both local and international markets. ANDRITZ (China) Ltd. Wuxi Branch, China, is an experienced competence center for production, service, and R&D especially geared to fit the Asian nonwovens industry. It designs and manufactures cutting-edge nonwoven machines to complement the ANDRITZ aXcess product range, designed with focus on the Asian markets.

ANDRITZ has built up the Wuxi facility on a par with European standards to better serve nonwovens producers and respond to customers’ requests promptly with top-end quality products. The ANDRITZ Wuxi branch is now optimally structured to focus on increasing efficiency and decreasing delivery time. Trained by European experts, the local project management team benefits from top-level expertise and the design department can make use of the most advanced software. A new service organization has been set up to enhance prompt delivery and provide excellent customer support.

The facility’s proximity to customers ensures a full range of services, including a roll service center with state-of-the-art grinding equipment and a test stand for various kinds of rolls. This is why all roll types can be repaired, reconditioned, and upgraded there on the spot.

ANDRITZ AXCESS PRODUCT RANGE FOR MEDIUM-CAPACITY PRODUCTION

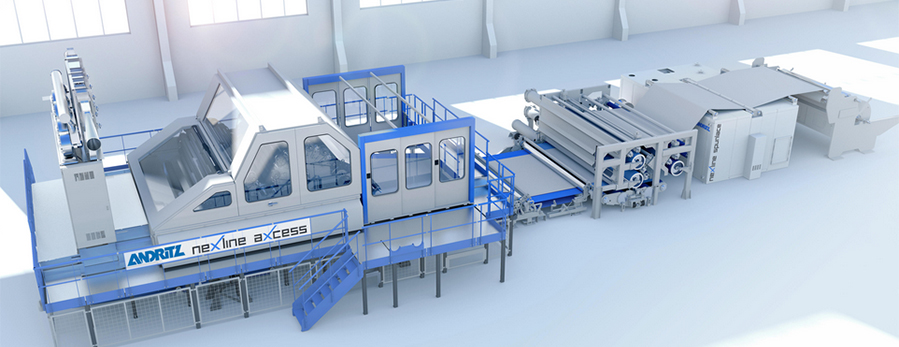

As an all-round partner for the nonwovens industry, ANDRITZ has developed the nonwoven aXcess range especially suited to the demands of producers with medium-capacity requirements, particularly in the emerging markets. The ANDRITZ aXcess portfolio includes lines and individual machines for air-through bonding, needlepunch, spunlace, wetlaid, and calendering processes, making it the ideal product for entering the nonwoven market with medium-capacity production.

The latest development in this segment, the neXline wetlaid aXcess devised for low to medium-capacity production, offers added value for producers. Compact lines make shipment easy, and they also fit perfectly into containers so that transport is fast. An operator-friendly configuration and versatile design ensures efficient and on-the-spot production at affordable investment costs.